Exactly How Membrane Layer Changes Add To the Sturdiness of Electronic Control Panels

Membrane buttons play a vital duty in improving the resilience of electronic control panels, largely through their multi-layered construction which supplies effective security against environmental factors such as wetness and dirt. This design not only reduces the threat of circuit damages and corrosion however likewise advertises simplicity of maintenance as a result of its seamless surface area. The lack of moving components dramatically decreases the possibility of mechanical failures, making membrane layer switches over ideal for requiring applications. The effects of these functions expand past plain security, increasing concerns regarding their wider effect on functionality and customer experience.

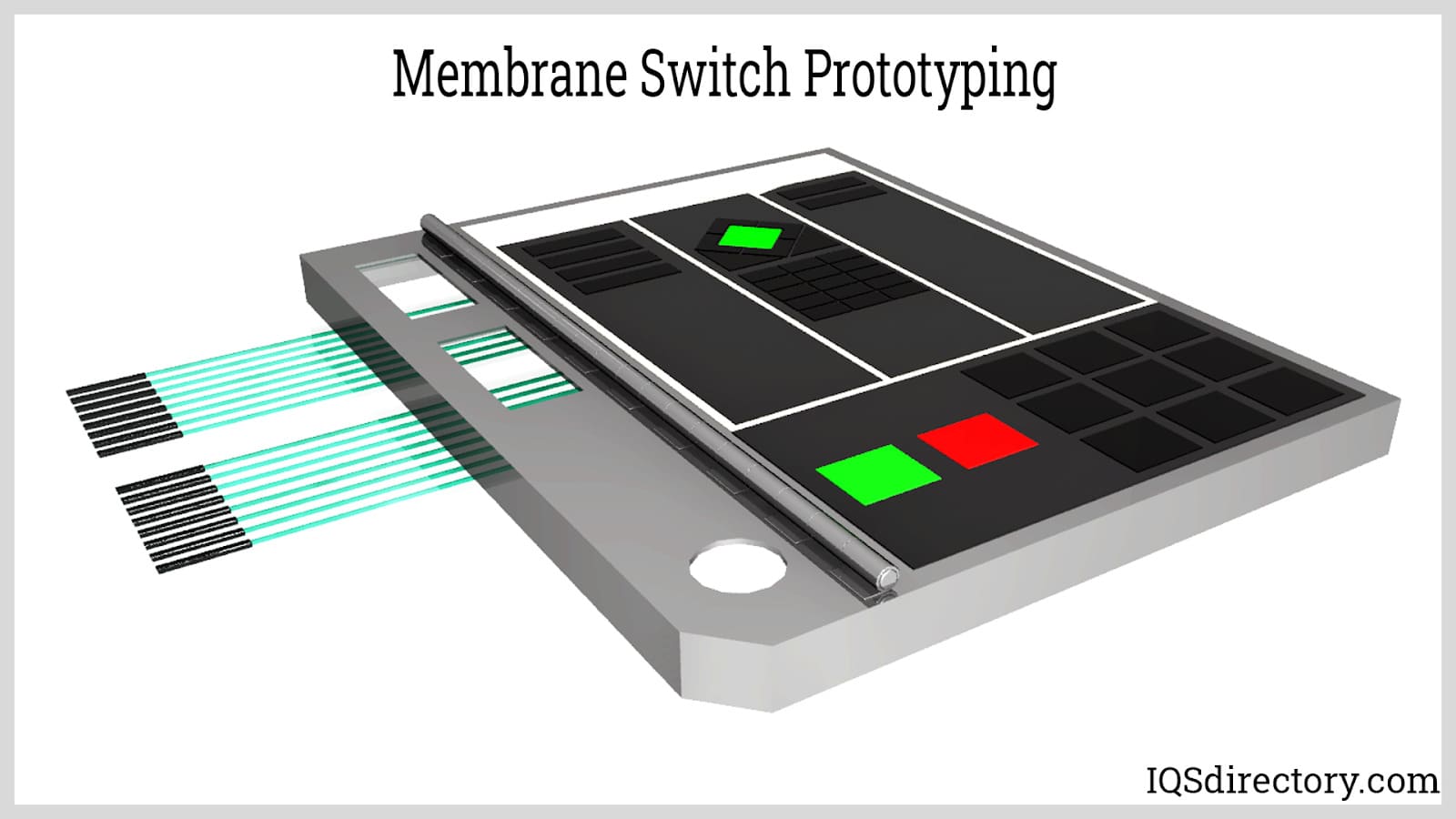

Meaning of Membrane Layer Buttons

Membrane layer buttons are designed to be thin and lightweight, making them appropriate for applications where area is limited. They can be made in various forms, dimensions, and colors, offering adaptability in layout that satisfies aesthetic and functional needs. Furthermore, membrane layer switches can incorporate numerous modern technologies, such as responsive responses and LED indications, improving individual experience.

Due to their building, membrane buttons are commonly resistant to dirt, dampness, and basic wear, adding to their longevity popular settings. Their seamless layout not only promotes very easy cleaning yet likewise minimizes the risk of mechanical failing, making them a preferred option for manufacturers looking for reputable interface in their digital control panels.

Protection Versus Environmental Factors

The layout of membrane layer changes inherently provides a level of defense versus various ecological elements, which is vital for keeping capability in tough conditions - Membrane Switch. These buttons are usually constructed with layers of adaptable products that protect inner elements from wetness, dirt, and pollutants. By enveloping the circuitry, membrane layer switches over decrease the risk of brief circuits and rust, which can dramatically impair performance

Moreover, the use of durable adhesives and sealants during production enhances their resistance to environmental difficulties. Membrane buttons can sustain direct exposure to chemicals and solvents, making them ideal for sectors such as food handling and healthcare, where hygiene and sanitation are vital. Their seamless surface area layout likewise protects against the build-up of dust and bacteria, facilitating simpler cleaning and maintenance.

Temperature fluctuations are one more ecological problem, and membrane layer buttons are engineered to function successfully throughout a broad range of temperature levels (Membrane Switch). This versatility makes sure that control board stay functional in numerous setups, from industrial settings to consumer electronics

Influence On Individual Communication

Individual communication with digital control board is significantly influenced by the layout and functionality of membrane layer switches. These switches offer a responsive user interface that boosts the overall customer experience, permitting user-friendly navigating and control. Their responsive nature makes certain that users receive immediate feedback upon activation, which is important for jobs calling for precision and effectiveness.

Additionally, the smooth surface area of membrane switches promotes very easy cleansing and upkeep, promoting individual confidence in the integrity of the user interface. This cleanliness is particularly crucial in environments where hygiene is paramount, such as medical or food handling setups. Furthermore, the portable and lightweight find here style of membrane layer changes adds to the aesthetic appeal of control board, urging customer interaction through a modern-day and streamlined appearance.

Additionally, the integration of visual components, such as published icons and backlighting, aids individuals promptly identify functions, decreasing the finding out contour related to new tools. As an outcome, individuals can operate devices more efficiently, leading to raised productivity and contentment. In recap, membrane layer buttons play a crucial role in improving customer interaction by combining functionality, appearances, and convenience of use, ultimately causing boosted functional performance.

Style Versatility and Modification

Style flexibility and customization are necessary facets of membrane buttons, making it possible for producers to tailor electronic control board to particular applications and user demands. This adaptability permits the integration of numerous style components, such as colors, graphics, and textures, which can improve the aesthetic charm and individual interaction of the control panel.

Membrane buttons can be customized in dimension and shape, suiting a wide variety of tools and applications, from industrial machinery to consumer electronics. This convenience makes sure that suppliers can develop user-friendly user interfaces that align with user assumptions and functional demands. Additionally, the capability to incorporate unique attributes such as backlighting or tactile responses even more improves functionality, enabling a much more interactive experience.

In addition, the production process for membrane switches sustains the fast prototyping of styles, allowing producers to repeat and refine their ideas quickly. This capacity not only speeds up the advancement timeline however additionally makes certain that the last product fulfills details useful and visual criteria.

Cost-Effectiveness and Long Life

Cost-effectiveness and long life are this hyperlink significant advantages of membrane buttons, making them an eye-catching option for manufacturers and end-users alike. These buttons are commonly less pricey to generate than conventional mechanical switches, mostly due to their streamlined production procedures and the reduced number of components required. This cost benefit expands not only to preliminary production but likewise to lasting functional costs, as membrane buttons commonly call for less upkeep and have a lower failing price.

In addition, the longevity original site of membrane layer changes contributes to their total worth. Constructed from long lasting products, they are resistant to ecological variables such as moisture, dust, and chemicals, which can lead to early wear in various other switch types. The absence of relocating parts reduces mechanical failure, permitting membrane layer switches to preserve functionality over prolonged periods.

This longevity is specifically useful in applications calling for constant efficiency under requiring conditions, such as clinical devices and commercial devices. Ultimately, the mix of cost-effectiveness and longevity makes membrane layer changes an economically viable option for suppliers, supplying reputable solutions that stand up to the examination of time while optimizing budgetary considerations.

Verdict

In verdict, membrane layer switches considerably improve the longevity of electronic control panels through their robust building and construction and protective features - Membrane Switch. Overall, membrane layer changes represent a trusted and cost-effective choice for boosting the durability and performance of electronic control systems.

Comments on “How to Make Certain Longevity and Integrity with a High-Quality Membrane Switch”